What AI’s Energy Demand Means for Lithium Supply Chains

Artificial Intelligence (AI) is rapidly emerging as a transformative force – reshaping society, industries, and now, energy systems. One of its most significant, yet less talked about, impacts is the sharp rise in electricity consumption. Powering AI at scale requires immense computing infrastructure: from large language models, real-time inference, cloud computing and machine learning workloads – all of which rely on data centers.

These data centers require continuous, 24/7 power, with minimal tolerance for fluctuations or outages. As AI workloads grow, so does the need for uninterrupted electricity. By 2030, global data center electricity consumption is expected to more than double, reaching approximately 945 TWh (as per IEA) – surpassing Japan’s current annual consumption. Fastmarkets reports that data center-specific storage capacity is projected to grow at a 35% CAGR through 2030, with AI as the primary driver.

Bridging the gap with energy storage

To address the mismatch between variable renewables generation and constant data center demand, operators are turning to energy storage systems (ESS). These systems store surplus energy, and release it when needed, ensuring uptime for mission-critical applications and managing peak loads.

This is where lithium plays a critical role.

Battery energy storage systems (BESS), particularly those based on lithium-ion batteries, have become critical in meeting the dual challenges of reliability and sustainability.

They are especially integral to uninterruptible power supply (UPS) infrastructure, providing instant backup during power outages unlike diesel generators that require minutes to start up. This is especially critical for AI and other high-demand workloads, where even seconds of downtime can lead to significant financial and operational losses.

In many cases, lithium-ion batteries are deployed in “second life” applications – repurposed after use in EVs or other devices – extending their lifecycle before disposal or recycling. Their environmental advantages also make them a preferred choice, especially as power grids continue to decarbonize.

KBR’s role in enabling this shift

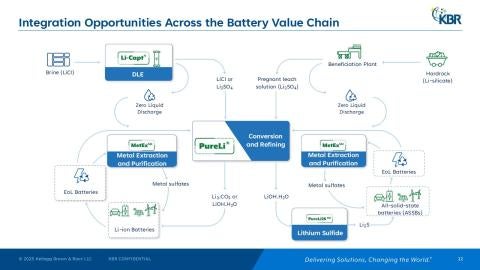

KBR supports this growing demand with advanced technologies for the production of battery-grade lithium compounds, essential inputs for lithium-ion batteries, used in both grid-scale and distributed energy storage systems.

We offer an integrated suite of lithium technologies, designed for efficiency, scalability, and sustainability across the value chain. From extraction to refining, our solutions help producers bring more lithium to market, faster and with a lower environmental footprint.

Direct Lithium Extraction with Li-Capt®

Through our global alliance with Geolith, KBR offers Direct Lithium Extraction (DLE) with Li-Capt® technology. This technology facilitates the efficient recovery of lithium from:

- Geothermal brines

- Oil and gas field brines

- Salars and continental brines

- Battery recycling and other unconventional lithium resources

DLE offers significant advantages over traditional evaporation methods, including reduced time, lower carbon footprint and decreased water consumption.

Refining and conversion to battery grade Li2CO3 or LiOH.H2O with PureLi®

Following extraction, KBR’s PureLi® refining and conversion technology supports the production of battery-grade lithium carbonate or lithium hydroxide monohydrate for use in lithium-ion batteries.

Extraction and purification with MetExSM

KBR’s MetExSM technology enables the extraction and purification of battery metal salts – including lithium – from diverse feedstocks such as ore concentrates, spent electrolytes, and e-waste.

“AI is accelerating global electricity demand, with data centers requiring around-the-clock, reliable power,” says Hari Ravindran, Senior Vice President, Technology Solutions, KBR. “KBR is enabling this shift with technologies that support battery energy storage systems – contributing to grid resilience and energy security.”

Together, our technologies support efficient lithium extraction from diverse sources and its conversion to battery-grade lithium – achieving average lithium recovery rates above 80% across the entire flow scheme from brine to producing battery grade lithium.

As AI infrastructure expands and grid storage becomes a strategic priority worldwide, pressure on lithium supply chains will only grow. KBR is helping clients stay ahead of that curve by making lithium production more domestic, efficient, flexible, and responsive to these new demand drivers.