Powering the International Space Station: KBR Personnel Play Key Roles in NASA’s New Solar Arrays

KBR flight controllers, instructors, and other experts at NASA’s Johnson Space Center in Houston, Texas, provided support for a trio of recent spacewalks to install new solar arrays on the International Space Station (ISS).

KBR personnel helped plan, install, and deploy the ISS Roll Out Solar Arrays (iROSA), which included training the astronauts who accomplished the task, choreographing their activities, and troubleshooting issues.

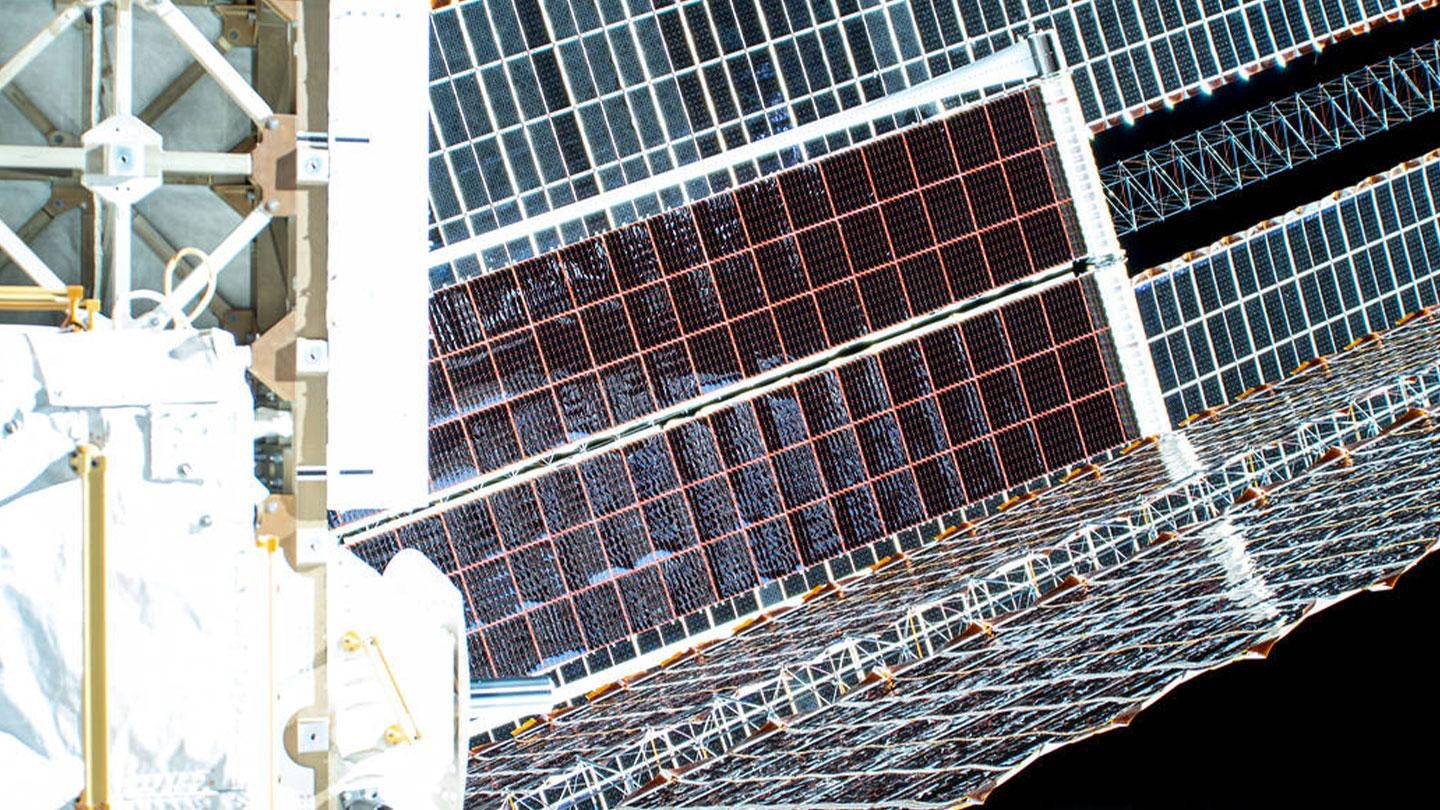

The space station uses solar arrays – large groupings of solar panels – to collect energy from the sun, which in turn provides electrical power for operations. On the station, solar arrays are set up in pairs. The arrays were designed for a 15-year service life and have been operating continuously since the first pair was deployed in December 2000. As expected, the old arrays began showing signs of wear after continued daily use for more than 20 years providing power for dozens of crews and thousands of scientific experiments.

As part of the project, NASA plans to augment three of the original four solar array pairs by adding new, smaller array pairs that “roll open,” resulting in a 20-30% increase in energy. To make this happen, NASA planned at least two spacewalks, or Extravehicular Activities (EVAs), to deploy each array pair.

KBR’s Integrated Mission Operations Contract (IMOC) II Lead EVA Officer Kieth Johnson led the team responsible for the development, training, and execution of the entire spacewalk sequence.

Step 1: Development

Johnson worked directly with KBR’s Bridget Scheib, who was in charge of developing the procedures to install and deploy the iROSA.

This iROSA spacewalk team followed along with the development of the hardware to ensure the crew’s perspective was considered from the early design phase until the hardware was installed on the space station. Johnson worked alongside Scheib to develop spacewalk timelines and the choreography required for installing the hardware once on orbit.

For complex missions that require transporting large hardware such as this, the solution usually involves the Space Station Remote Manipulator System, otherwise known as the space station’s robotic arm. The arm is used to move modules or crew members into difficult positions when working on the station.

“Since the solar array needed to be moved to the far side of the station, we planned for the astronauts to ride on the robotic arm as an aid while holding the new array,” said KBR IMOC II Robotics Mission Designer Dominick Prete, who began developing different robotic positions and trajectories for the spacewalk nearly a year in advance.

Together with his team, Prete tested their robotics both on the ground in the NASA Virtual Reality Lab and at the Neutral Buoyancy Lab (NBL) in Houston. The NBL is the world’s largest indoor pool and is filled with 6.2 million gallons of water; at the bottom of the pool sits a full-scale replica of the space station that astronauts and space professionals use frequently for key training and testing procedures.

“Once those robotics tests are solidified, I help write the procedures containing that information for the crew to use,” Prete said.

“Normally our team performs robotics-only activities from the ground, but for most EVAs, we have two crew members on the space station control the robotics for security and safety purposes. We stand by in the mission control center watching them operate it in case any discrepancies come up and we can make changes in real time.”

Step 2: Training

Johnson and his team also utilized the NBL to determine the best way to remove the solar array from its leg support equipment once docked and transport it onto the ISS. “We practice a lot of test runs and simulations, as well as train the crew members on how to install everything,” he said.

While spacewalks can be planned for specific dates and times, there are still many variables. “You have to train multiple sets of crew members because you can never be 100% sure who will be there on the day of install,” Johnson continued.

In fact, all crew members get nine NBL training runs – six for standard contingency scenarios and three dedicated to EVAs they might perform. “It’s very important that when we do these NBL runs, the crew fully understands the hardware, timing, and choreography. There is a lot of fine tuning,” Johnson said.

In preparation for the mission, employees from the Houston Engineering Logistics and Operations team on KBR’s Extravehicular Activity Space Operations Contract (ESOC) processed and delivered the tools to be used during the EVAs.

These include Extravehicular Mobility Units (EMUs), more commonly referred to as spacesuits, along with support equipment fit checks at Kennedy Space Center. KBR experts also worked directly with NASA’s SPARTAN (Station Power, Articulation, Thermal and Analysis) team responsible for power generation on the station.

“This particular set of EVAs was more challenging than most because of the solar array positioning and having to lock them in just the right place,” Johnson said.

Location is key because similar to the sun creating shadows on Earth, shading can affect a solar panel’s ability to generate power in space, too.

“Every aspect of this was like threading a needle,” he continued. “The International Space Station must also be configured in a specific position so the robotic arm can reach the port side of the station for install of the new arrays.”

Step 3: Execution

Once the station and hardware are in position, the main challenge becomes the spacewalk itself. In this instance, the new solar arrays had limited handrails in order to fit into the delivery vehicle.

“This made it more complicated,” Johnson said. “We had to figure out the best way to hold on to the large array and pass it from one crew member to the next. Additionally, we had to think through potential troubleshooting – what if a bolt fails or the robotic arm gets stuck?”

Johnson and his team spent a lot of time dissecting potential failure scenarios while planning. As engineers, we think through everything that could possibly go wrong and evaluate a workaround for each scenario,” he said. “The job is always to keep the EVA moving forward, managing the timing, monitoring suit parameters, and working together to inform the flight controllers.”

One issue that did arise during the first spacewalk included a suit display error message. “The suit has displays that show messages to the crew and it froze up.” Johnson said. “Going back to the airlock for a warm restart resolved the issue.”

On top of the initial set back, the team also had trouble getting the new solar array to fully swing open into position. The NASA ground crew, along with KBR personnel, helped troubleshoot and determine a solution. “We used computer-aided design (CAD) models, or mockups, for the second EVA to get the iROSA to fully open and used the same plan for the second iROSA on the third EVA.”

In the end, KBR personnel collaborated with each other and NASA to complete the installation and deployment of the first array. The crew repeated their success with deployment of the second array during the third spacewalk on June 25. Totaling 20.5 hours, the three spacewalks were designed, planned, trained, and executed by KBR employees in collaboration with NASA.

“When you get done with a mission like this, it’s hugely rewarding,” Johnson said. “You still have to think about how to make it better next time, but it’s cool to reflect on how we helped the big picture in our own, small unique way.”

As space efforts continue to grow, more power will continue to be needed on the space station.

“Nowadays, we have new visiting vehicles, and are doing new operations all the time. We’re very much still pushing the envelope and doing new things, and this power helps with all that,” Prete said. “I was honored and excited to be part of this historic project. Being on console and watching all of our work come to fruition was really amazing.”

The space station currently has 10 solar arrays on station – four older pairs plus the two new iROSA arrays, which were installed on top of the original arrays. It was the first job in a series of assignments to identify six of the station’s eight power channels to update – each channel represents a separate energy source.

Post-completion, the majority of power will come from the new arrays. Additionally, the iROSAs are serving as a test for NASA’s Artemis Gateway, a small space station that will orbit the Moon.

“This kind of large-scale power generation means we can support more science,” Johnson said. “It was a wonderful project to be a part of and to our partners at NASA take a step closer to the moon, and beyond.”